How does galvanized steel protect itself from corrosion?

What are some common uses for galvanized steel?

Does galvanized steel need to be painted?

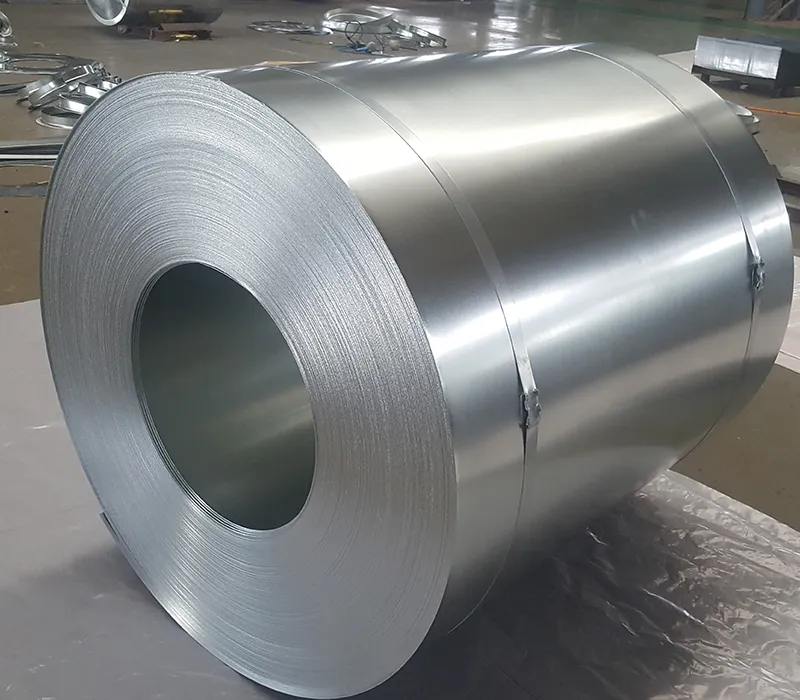

Assessing Surface Quality of Hot Dipped Galvanized Steel?

To ensure optimal performance, the surface quality of galvanized steel is evaluated based on the following criteria:

- The superior surface of the steel coil features a uniform zinc coating, free from defects that could impact functionality. Minor marks like faint indentations, slight scratches, or subtle chromate passivation streaks may occasionally appear but won’t affect performance.

- The opposite surface might show minor imperfections such as small zinc particles, uneven spangles, or light dark spots. Slight zinc layer variations, fine air knife marks, and small dross residues are also within acceptable limits and do not compromise product quality.

Note:

Due to the continuous nature of the production process, minor surface flaws are inevitable. While national standards allow defects in up to 6% of a coil’s length, we maintain stricter quality control, ensuring that defects are limited to 3% or less, providing a more reliable product for our customers.

What factors should I keep in mind when selecting pre-painted steel?

What’s the composition, function, and types of coil coatings?

Pre-painted steel relies on coil coatings to deliver both protection and visual appeal. These coatings are composed of four main components: resins, pigments, solvents, and additives. Each layer is important to enhance the steel's performance and durability. The solvent, as the volatile element, evaporates during the curing process, leaving a solid, protective film that ensures long-lasting performance.

- Resins

Resins are the most important part of the coating, often referred to as the binder. They form the protective film on the steel surface and are fundamental in determining the coating’s performance, including durability, flexibility, and resistance to weathering. Resins need to remain stable during storage, without undergoing significant physical or chemical changes. During application, resins cure quickly under the right conditions to form a solid, protective layer. Commonly used resins in coil coatings include acrylic, epoxy, polyester, and polyurethane. Each resin type offers different levels of protection and durability depending on the specific needs of the application, such as improved corrosion resistance or better weather performance. - Pigments

Pigments are combined with resins to provide color and opacity to the coating. However, their role is not just aesthetic. They also influence other important properties like hardness, gloss, and corrosion resistance. By adjusting the pigment-to-resin ratio, coatings can be customized to achieve the desired level of performance and appearance, balancing durability with visual appeal. - Solvents

Solvents are an important component of liquid paints, acting as volatile substances that evaporate during the drying phase. Solvents are commonly used to adjust the viscosity of the paint, ensuring smooth application and even coverage. This substance has an important role in the production, storage, application, and film formation of paints, significantly influencing the quality and durability of the coating. - Additives

Used in small quantities, additives are capable of enhancing the coating’s performance. They are designed to improve properties such as drying time, leveling, and defect prevention. Common examples include curing agents, defoamers, stabilizers, and matting agents. Each additive is carefully selected to meet the performance requirements of the coating, ensuring it functions optimally in various environments.

Types of Coatings

- Topcoats

Common topcoats include polyester, silicone-modified polyester, high-durability polyester, and polyvinylidene fluoride (PVDF). Each type of topcoat offers different levels of hardness, flexibility, and corrosion resistance. Polyester is the most widely used due to its good balance of durability, hardness, and flexibility, all at a reasonable cost. Silicone-modified polyester provides better durability and improved gloss and color retention but sacrifices some flexibility. High-durability polyester combines the advantages of standard polyester with enhanced longevity, offering excellent value. PVDF stands out for its exceptional durability and flexibility, though it has lower hardness, fewer available color options, and a higher price. How to choose the best topcoat will depend on factors such as the intended application, environmental conditions, lifespan, and processing requirements. - Primers

The primer layer is important in the coating system as it improves adhesion and provides an additional layer of protection against corrosion. Different primers offer unique benefits depending on the specific requirements of the application. Epoxy primers bond exceptionally well to the substrate and deliver high corrosion resistance, though they tend to be less flexible. Polyester primers, on the other hand, provide excellent flexibility and strong adhesion but offer slightly lower corrosion protection compared to epoxy. Polyurethane primers provide a well-rounded performance combining solid corrosion resistance, flexibility, and adhesion, making them a versatile choice. The selection of primer typically depends on factors such as the production process, intended use, environmental conditions, and compatibility with the topcoat. For detailed performance characteristics, consulting technical resources or industry experts is recommended to ensure the best fit for each application. - Coating Thickness

The thickness of the coating layer is closely linked to the corrosion resistance of pre-painted steel. Generally, a thicker coating offers better protection against corrosive environments. The appropriate coating thickness should be determined based on factors such as environmental conditions, expected lifespan, and durability requirements. - Color Consistency

Color variations can occur during both production and use due to factors like batch production, color depth, exposure time, and environmental conditions. To avoid misunderstandings, it’s recommended that suppliers and customers agree on acceptable color variations when placing an order. - Gloss Level

Gloss levels are typically selected based on the intended application and user preferences. For example, pre-painted steel used in construction often features medium to low gloss, while high gloss is preferred for home appliances to create a polished, attractive finish. - Coating Hardness

Hardness measures the coating’s ability to resist scratches, friction, impacts, and indentations. This property is closely related to scratch resistance, wear resistance, and pressure resistance. The right level of hardness should be chosen based on the intended use, processing method, and storage or transportation conditions. - Flexibility and Adhesion

These properties are essential for ensuring the coat's adaptability during processing. They determine how well the coating can handle deformation without cracking or peeling. For applications involving high deformation or fast processing speeds, materials with high impact strength and low T-bend values are recommended to maintain performance and appearance. - Coating Durability

Coating durability refers to how well the coating performs over time, typically measured by its lifespan under real-world conditions. Several factors influence durability, including the type of coating, its thickness, and the corrosiveness of the environment. While real-world performance provides the most accurate measure, artificial aging tests are commonly used for initial evaluations. Neutral salt spray tests are among the simplest and most widely used methods to simulate aging, providing insights into corrosion resistance. Additionally, UV lamp accelerated aging tests help evaluate how coatings withstand prolonged exposure to sunlight. For environments with specific challenges, such as acid rain or high humidity, specialized artificial aging tests should be conducted. However, it’s important to note that these tests cannot fully replicate actual environmental conditions.

Which types of tests should be made for the steel coil coatings?

In specific applications, pre-painted steel may need enhanced resistance to organic solvents, acids, alkalis, and pollutants. These properties are crucial for maintaining durability in demanding environments. Below are the main tests used to evaluate these performance aspects:

Acid and Alkali Resistance Test

- Test Principle

This test involves immersing samples in solutions with specified concentrations of acids or alkalis for a set period. Once removed, the coating is evaluated for changes in color, gloss, and any signs of blistering or peeling. - Results Analysis

Results are assessed according to GB/T 1766 standards, including gloss loss, discoloration, blistering, and peeling. The lowest performance among parallel samples is recorded as the final result.

Neutral Salt Spray Test

- Test Principle

This test simulates exposure to a salt-rich environment to assess the coating’s corrosion resistance. Samples are placed in a neutral salt spray chamber for a specific time, after which surface conditions like blistering, rusting, and corrosion spread are examined. - Results Analysis

Flat samples are rated for blistering and rusting per GB/T 1766, with the worst results across parallel tests recorded. For scribed or cut samples, corrosion spread along the scribed line is measured at multiple points. The average, maximum, and minimum spread distances are calculated and documented.

Atmospheric Exposure Test

- Test Principle

Samples are exposed to outdoor conditions to evaluate the coating’s durability against natural elements such as UV rays, rain, and temperature fluctuations. The test measures how well the coating maintains its properties over time, including gloss, color, and physical integrity. - Results Analysis

1. Flat samples are evaluated for indicators such as gloss retention, color stability, chalking, blistering, rusting, and cracking. The worst-performing sample from the test batch determines the final outcome, ensuring a comprehensive understanding of the coating’s durability.

2. Stressed or damaged samples, including areas subjected to T-bends, impacts, scribing, riveting, and folding, are assessed for issues like blistering, rusting, and the spread of edge corrosion. Again, the most severe result across the batch is used as the benchmark.

3. Performance under natural atmospheric conditions can also be evaluated through reports provided by certified outdoor exposure facilities. These reports offer valuable insights into the coating’s long-term behavior in specific environments.

Why is the back coating important?

How should pre-painted steel be handled in different environmental conditions?

What are the differences between cold rolled and hot rolled steel?

What are the benefits of cold rolled steel?

How is cold rolled steel protected from rust?

What are common applications of cold rolled steel?

Cold rolled steel is favored for applications that require precise dimensions and a smooth finish. It’s commonly used in:

- Aerospace components

- Household appliances

- Modern metal furniture

- Precision strips, rods, and bars

- High-performance mechanical parts

What are the characteristics of hot rolled steel?

What are the applications of hot rolled steel?

It is commonly used in projects where precise dimensions and a smooth finish are not required. Some common applications include:

- Structural components (rail tracks, I-beams, metal plates)

- Agricultural machinery

- Metal buildings

- Stamped parts

- Automotive frames